Globalizing operation.

Facilitating integration.

Streamlining data flow.

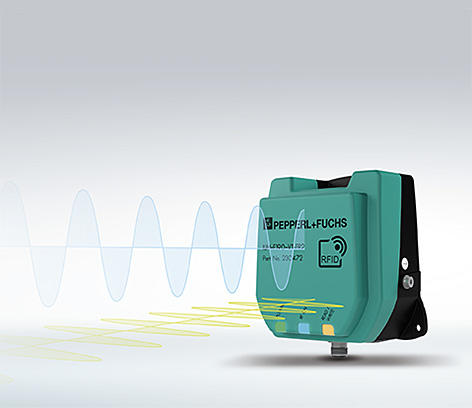

F190 and F192

RFID UHF read/write heads

Top Performance for Worldwide Operation

High compatibility for easy system integration

Switchable antenna polarization enables flexibility

Quick information gathering with multi-tag reading

360° - Explore the Mid-Range Version F190

High-End Technology Usefully Implemented

Switchable antenna polarization for safe processes

Both read/write heads offer the possibility of optimal polarization adjustment, depending on your application. In applications where tag orientation is steady or known, linear vertical polarization is ideal. You can fine-tune the adjustment of the antenna polarization to the tag and reduce the power level. When orientation of the transponder tag is unknown or may vary, automatic switching of both polarizations is the best choice. Using this approach, reliable detection is independent of tag orientation, e.g. when it comes to the identification of unsorted cargo.

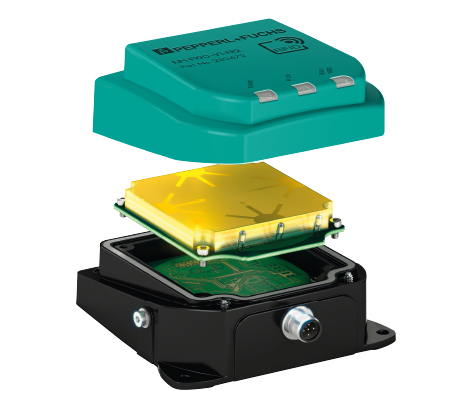

Robust RFID technology for harsh industrial environments

The F190 and F192 series of read write/heads are ideally suited for installation in challenging environmental conditions. Their rugged exterior and sealed electronics reliably protect both series against all kinds of wear and tear, including high temperatures. Possible space restrictions are no longer an issue thanks to the device design of F190 and F192: the UHF antenna is mounted inside the compact housing. This approach eliminates the need for extra components while at the same time allowing for easy installation in tight spaces.

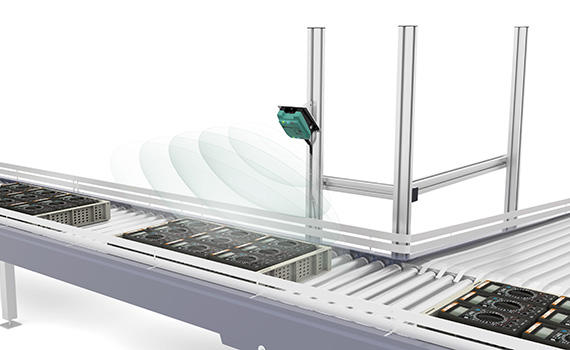

Use Cases

Material Handling Applications

Efficiency is top priority in intralogistics. Goods need to be transported to their place of destination fast, safe, and without any misassignment. For applications where it comes down to mounting space and where reading distances from 1 m to 2 m are sufficient, F190 is ideal. Transmitting data in one bundle, information from up to 40 tags can be transmitted to the read head in a single step.

To realize reading distances of more than 2 m, F192 extends the product family with outstanding features. With a range of up to 6 meters, this UHF read/write head is especially suitable for applications where long distances need to be covered. It is able to read and write on up to 200 tags at the same time, allowing an extremely fast throughput and significant productivity increase in material handling and intralogistics processes.

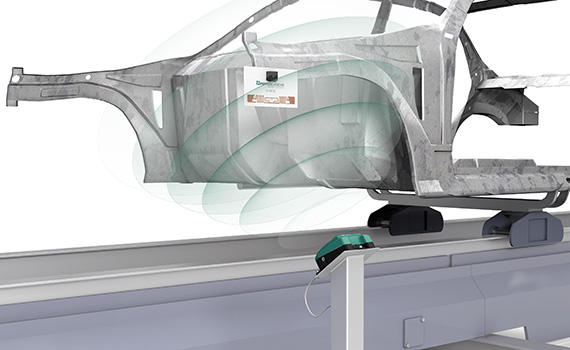

Automotive Applications

Automobile production can be controlled by transponders that are mounted on skids or directly on vehicles. In addition to reading the vehicle ID, the write function enables the modification of information for downstream production steps on the transponders. Even in challenging environments, like they frequently occur in the final assembly, both UHF read/write head series convince with their extreme reliability and flexibility.

With its compact built, the F190 is suited for mid-range applications, like shell container logistics or final assembly, while the F192 with its huge reading range is best used for larger distances, like they exist at test benches or hall gates. Both UHF read/write heads allow the selective fine-tuning of the read-range to block out possible interference by nearby processes, ensuring production flow at any time.

Contact Us

Simply send us an email to receive more information on the F190 and F192 RFID UHF read/write heads and RFID technology.

More information

More information

- F190 and F192 UHF Read/Write Heads All products from the F190/F192 series

Downloads

Downloads

+49 621 776-0

+49 621 776-0