Leading the way.

Reinventing positioning.

Revolutionizing safety.

safePXV and safePGV

SIL 3/PL e Absolute Positioning Systems

Maximum Safety—A Good Feeling

Safety applications according to "SIL 3/PL e" require strict compliance with the highest safety directives in order to optimally protect humans and machines at all times. While this safety level was previously associated with high cost and time investment, users now realize it more simply than ever before—with our new and worldwide unique "safePXV" and "safePGV" positioning systems.

Based on a multi-redundant technology, these systems enable safe absolute positioning according to SIL 3/PL e with one single sensor for the first time. safePXV offers the perfect solution for linear absolute positioning; safePGV for reliable navigation of automated guided vehicles (AGVs). Rely on this innovative sensor technology for maximum safety!

A Real Innovation

Benefits

Innovative Technology and High Flexibility

Convenient and Quick Assembly

Commissioning via Plug&Play

High-End Technology

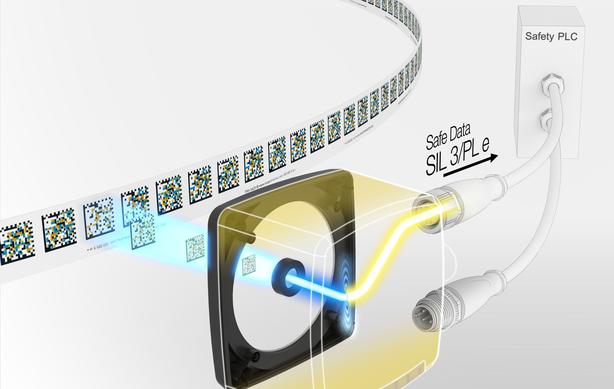

Safe data directly from the sensor

The 2-D read head of the new absolute positioning systems reads the color codes of the Data Matrix code band. The innovative firmware processes the received information based on a safe algorithm in the sensor and forwards it as safe data according to SIL 3/PL e to the safety PLC. You achieve this high safety level for the first time with a single sensor.

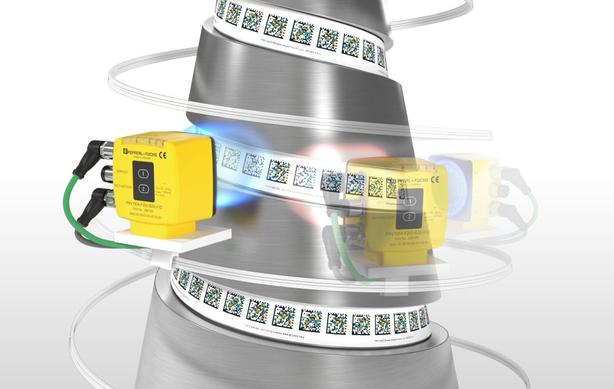

Multiple-redundant and flexible

Using Data Matrix codes as information carriers allows data to be redundantly mapped. The wide scan window provides additional redundancy by reading up to five Data Matrix codes in a single read operation. The positioning systems ensure reliable positioning even if multiple codes are dirty or damaged. Tight curve radius, strong ascents and strong descents, and line breaks of up to 75 mm are not an obstacle—on a unique distance of up to 100,000 m!

The New Generation of Positioning Systems on YouTube

With the new positioning systems, Pepperl+Fuchs sets new standards in terms of reliability, noise immunity, and handling. But what exactly distinguishes this sensor generation? In this YouTube video, you see its specifics using concrete application examples.

Versatile Safety Applications

safePXV—Safe Positioning

The safePXV positioning system offers unparalleled reliability for linear absolute positioning. Due to its easy handling, it is suitable for a variety of different applications. The image shows the safePXV ensuring exact positioning of monorail conveyors in a production line. Additionally, it is used for stacker cranes in material handling, rotary tables, or for elevators and wind turbines.

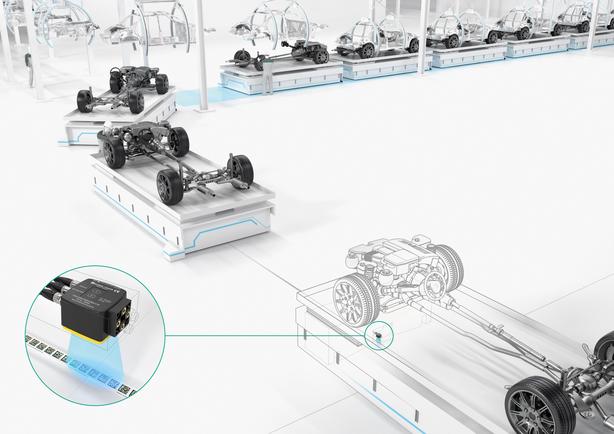

safePGV—Safe Navigation

In addition to absolute positioning, the safePGV positioning system provides all data needed to reliably control AGVs. These are used in production lines in automotive industry. By transmitting Y position and angle, track deviations can be continuously corrected. Due to the safe X position, safePGV ensures the safety distance between the AGVs and thus protects personnel.

Contact Us

Do you have any questions on our safePXV and safePGV positioning systems, or do you want to receive more information? We are happy to help! Simply fill out the contact form and send us a message.

Downloads

Downloads

More Information

More Information

- Data Matrix Positioning System (PXV, safePXV)

- Position Guided Vision (PGV, safePGV)

- Safety Revolutionized Take a look behind the scenes of this innovativ product development.

+49 621 776-0

+49 621 776-0