Our Solutions, as Individual as You.

Customized Solutions

As Individual As You

As production plants become more automated and process plants grow more complex, the tasks and challenges of our customers are changing. As automation experts, we would like to partner with you to pave the way for a digital future—with solutions as individual as you.

The experts at Pepperl+Fuchs plan, develop, and implement customized solutions that are tailored to the needs and applications of our customers in both factory automation and process industries. Because every customer and every project is unique. We take care of every step, from the first draft to the ready-to-use solution. This is so you can focus on your core business and leave your automation tasks in the hands of a specialist.

No matter whether you need a custom design, a new mounting option, or a complete package of individual components and software—we will use our passion for automation and technical know-how to find the solution that works best for you. Because for us, solutions are only technically perfect if they solve your problem completely.

Watch our video to see an example of a joint solution.

Learn more about the Solution Engineering Centers in our video.

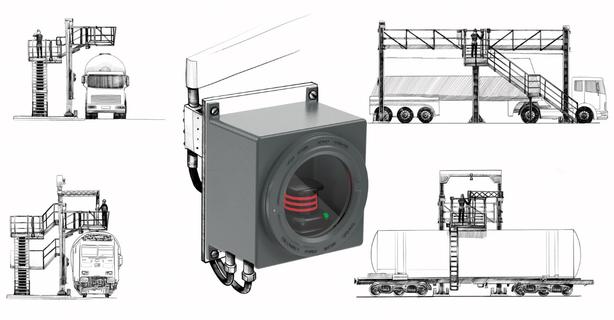

Story: Everything in View

Whether in tank trucks by road or in tank cars by rail: Chemicals must be transported with caution because more than 40 percent of the products are classified as hazardous. Despite this high percentage of high-risk freight, the procedure for filling vehicles and train cars with these substances is not always the same since gases, liquids, and granules have different properties. In addition, there is often a risk of explosion. This means creative solutions are needed to provide the necessary level of safety. Pepperl+Fuchs developed a customized solution that makes loading safer and more efficient.

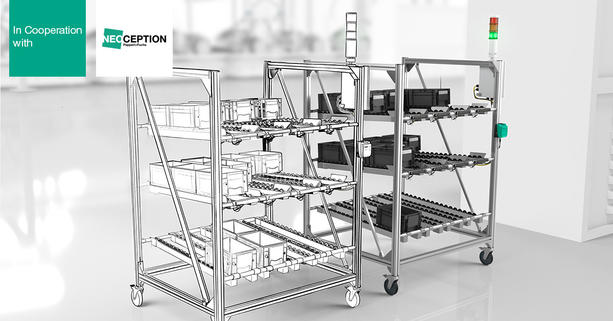

Story: Next-Level Kanban

Kanban systems are indispensable in manufacturing plants and offer many advantages. Nevertheless, error-prone manual workflows and low digitalization mean that there is room for improvement. Bosch Connected Industry (BCI), Pepperl+Fuchs, and Neoception have partnered together to develop a complete solution that adapts Kanban racks for Industry 4.0 and is equally suited for greenfield projects and retrofits.

More Solutions

Powerful Network

Pepperl+Fuchs Group customers do not just benefit from our extensive know-how in electrical explosion protection and industrial sensor technology. With engineered product developments, tailor-made systems, smart automation systems for the aviation industry, and individual process analyses and IoT solutions—customers have access to a powerful network of experts.

The start-up Neoception, for example, develops innovative software solutions and industrial IoT services that are tailored to customers' business processes and requirements. Using customer-specific analysis, the team helps increase the efficiency of plants and processes, and taps into hidden potential.

Our focus is always on your individual requirements. Fueled by a passion for automation and groundbreaking technology, the companies of the Pepperl+Fuchs Group are committed to working in partnership with you—now and in the future.

Challenge Us!

Do you have questions or a task for us to solve? Get in touch with us. We look forward to hearing from you.

More Information

More Information

- Intrinsically Safe Mobile Devices Discover our mobile worker solutions!

- Neoception Learn more about industrial IoT services!

- VMT Vision Machine Technic Discover customized vision solutions by VMT!

+49 621 776-0

+49 621 776-0