WILSEN.sonic.level

IoT Sensor for Smart Fill Level Management

WILSEN.sonic.level

Convenient Device Management via Mobile Device App

Standardized LPWAN Technology for High System Flexibility

Ultrasound Expertise from the Market Leader

Optimize your Business Processes with Sensors for the Internet of Things

Wireless IoT sensors make containers, tanks, and silos smart. The WILSEN.sonic.level battery-operated wireless level sensor is used primarily in the smart city, smart logistics, smart farming, and smart environment sectors. The sensor parameters allow it to be adjusted for a very diverse range of installation conditions and for detecting different materials.

The standardized LoRaWAN® technology allows the sensor to autonomously transmit the relevant data over a range of many kilometers for several years. The WILSEN.sonic.level therefore combines all of the important properties required in challenging industrial application scenarios with the connectivity and manageability of an IoT sensor.

As a member of the LoRa Alliance®, Pepperl+Fuchs is commited to delivering product interoperability and worldwide deployment of this technology.

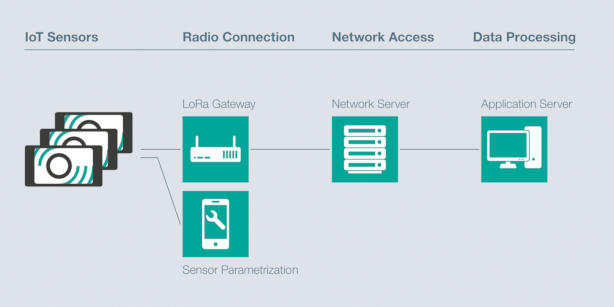

The IoT System

Alongside the sensors and data transfer, an IoT sensor system includes the sensor data receiving point on the internet. In LoRaWAN® systems, the gateway is responsible for converting the sensor data into an Ethernet-compatible protocol.

It sends the converted data to the network server, which first decrypts the data and then forwards it to the relevant application server. The sensor data is processed there and is ready to be depicted on the graphical display.

The WILSEN.sonic.level sensors are conveniently parameterized using a mobile device app so that they are optimally configured for the required application at the operating location.

How Does It Work?

The IoT Sensor

Multisensor

The WILSEN.sonic.level transmits more than just fill level data. GPS data from the sensor allows containers to be tracked, while further information such as temperature values and battery charge status allows for predictive maintenance.

Mobile Device App

The WILSEN.sonic.level eliminates the need to laboriously adjust individual sensors via push buttons since parameterization and network registration are carried out on the mobile device using an Android app (WILSENcontrol) via Bluetooth® LE.

Standardized

The WILSEN.sonic.level is not tied to specific systems—it can be integrated into any LoRaWAN® network. It is easy to use vendor-independent software and quickly develop and customize IoT solutions.

Industrial Use

Its suitability for industrial use sets the WILSEN.sonic.level apart from other IoT sensors—it has a rugged housing with IP66/67 protection and can also be used outdoors at temperatures of -25 °C … +70 °C.

Smart Environment

The wireless sensor WILSEN.sonic.level monitors fill levels of rivers, lakes and flood basins. It transmits additional information such as temperature, geolocation and battery status even across many kilometres helping to better protect against flooding.

Applications

Smart Farming

Modern agriculture supplies both food and energy. The WILSEN.sonic.level helps farmers to remotely monitor fill level of distributed feed silos or the pit of a biogas plant. By using such an IoT system, it relieves the farmer of inspection rounds and creates space for important tasks in his efficient operation.

Smart Logistics

Efficient supply chains in a globalized world must not run out of raw materials and supplies. The WILSEN.sonic.level helps to determine the fill level in tanks or silos and gives the supplier the opportunity to offer their customers a supply logistics system that is tailored to their needs.

Smart Cities

The demands placed on cities and municipalities to provide citizens with convenient, environmentally friendly living arrangements are increasing. The WILSEN.sonic.level enables intelligent disposal management, in which the filling levels of used glass, old clothes, and recyclables containers are monitored remotely so that the containers are only collected once filled to a set amount.

LoRa Technology

Numerous Advantages for Your Applications

LoRa technology features a number of advantages that are especially suitable for use with IoT sensors such as the WILSEN.sonic.level:

- Connection of devices up to 15 km away; can penetrate building walls

- Global availability and vendor independence for quick deployment of IoT applications

- Minimal power use during transmission, meaning that a sensor can function for years without changing the battery

- Data transfer via radio, therefore no sensor cabling requirements

- High security and integrity thanks to authentication and end-to-end encryption

- Low operating costs due to use of a license-free frequency band

These properties mean that LoRa can be used to create very large wireless networks to implement applications for cities and municipalities. It can also be used to set up cost-effective private networks on company premises. The diagram on the right shows the topological differences of the versions.

If you want to learn more about the advantages of LoRaWAN®, feel free to read our online article:

Contacto

Download

Download

More Information

More Information

- WILSEN.sonic level Discover the wireless ultrasonic sensor with LoRaWAN interface

- LoRa Alliance

+49 621 776-0

+49 621 776-0