Ethernet Advanced Physical Layer

The fastest and most efficient way to continuously communicate large amounts of data from hazardous areas to the cloud

Ethernet-APL—for IIoT Applications in Process Industries

Industry 4.0 and the Industrial Internet of Things are standard in the manufacturing industry. In the process industry, on the other hand, there was previously no network standard capable of quickly transferring large amounts of data from the field level to the information level of the Industry 4.0 architecture.

With the new Ethernet advanced physical layer, Ethernet-APL for short, Pepperl+Fuchs and other companies are now setting a major milestone. Ethernet-APL includes long cable lengths, explosion protection, and interoperability, enabling continuous and transparent communication across all hierarchy levels. Learn more about the pioneering technology that is paving the way for demanding IoT applications in the process industry.

Highlights

Benefits

Increased Plant Availability

Simple, Cost-Effective Plant Modernization

Flexible Use Worldwide

Working Together to Create a New Standard

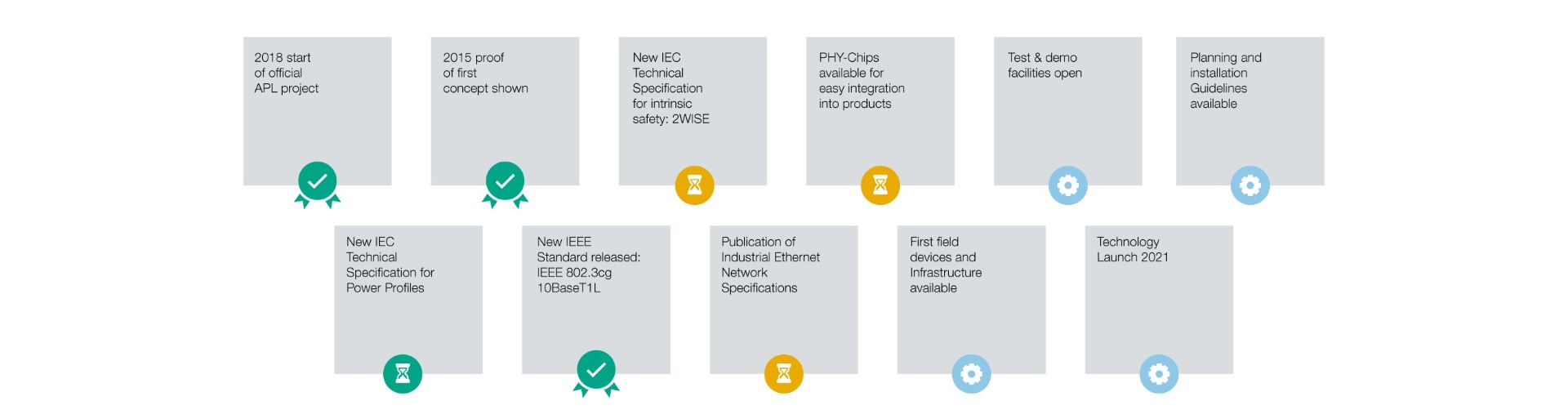

For the global process industry, the effort to standardize the physical layer of a communication system is a unique project. Supported by leading associations Fieldcomm Group, OPC Foundation, ODVA, PROFIBUS, and PROFINET International, as well as key players in the industry, the largest collaboration to date in the field of process automation has emerged. Along with the companies ABB, Endress+Hauser, Krohne, Phoenix Contact, Rockwell Automation, SAMSON, Siemens, Stahl, Vega, and Yokogawa, Pepperl+Fuchs is working on the development of the new "advanced physical layer" for Ethernet.

Ethernet-APL combines all the experience and needs of process professionals: long cable runs, two-wire lines, interoperability, and use in hazardous areas up to Zone 0/Class 1, Div. 1. As an expert in electrical explosion protection, Pepperl+Fuchs is actively driving these developments within the Ethernet-APL project. As early as 2015, a separate demonstrator showed a miniature version of process plant architecture with Ethernet-APL.

YouTube Videos

The Ethernet Advanced Physical Layer—or Ethernet-APL, for short—includes long cable lengths, explosion protection, and interoperability, enabling continuous and transparent communication across all hierarchy levels. The trailer offers a glimpse of this pioneering technology ...

In this video, Michael Kessler, Executive Vice President Components and Technology, Process Automation at Pepperl+Fuchs, demonstrates the typical communication architecture of a process plant with signal transmission via Ethernet …

The Ethernet Advanced Physical Layer fits any process plant as the installation architecture provides flexibility and explosion protection for all types of hazardous areas. The video illustrates typical topologies for process automation …

Review Pepperl+Fuchs' Online Summit

In this panel discussion, Gerd Niedermayer from BASF talked with experts from Pepperl+Fuchs about the challenges and advantages of future communication via Ethernet-APL within the process automation and the first test installation at BASF …

To provide the process industry with the Ethernet advanced physical layer, four attributes must be standardized: communication, power supply, installation, and explosion protection. Andreas Hennecke, Product Marketing Manager at Pepperl+Fuchs, illustrates these attributes in detail.

In this keynote speech, Michael Kessler, Executive Vice President Components & Technology at Pepperl+Fuchs, covers the factors that led to the largest collaboration in the history of the process industry …

Topologies

Compact Plant Layout

Ethernet-APL is designed to support any relevant installation topology. This topology shows the infrastructure for compact or indoor installations as seen in chemical or pharmaceutical industries. Here, the Ethernet-APL field switches are typically located in junction boxes or control cabinets in non-hazardous areas or hazardous areas up to in Zone 2, Division 2. The maximum cable length is up to 200 m to the instrument. Explosion protection for any hazardous area includes intrinsic safety selectable for the instrument connection.

Long-Reach Plant Layout

This topology gives an example for long-reach installations as seen in the oil and gas industry. It enables cable lengths of up to 1000 m between switches on the trunk segment. Here, the Ethernet-APL field switches are designed for operation in hazardous areas, which are typically Zone 1 and 2 or Division 2. Normally, they are loop powered by the Ethernet-APL power switch and distribute both communication signals and power to the field devices via spurs. This Ethernet-APL installation also meets all requirements for explosion protection with increased safety or intrinsic safety. This topology provides a clear migration path for fieldbus users during brownfield projects.

Project Overview

Contacto

Do you have any questions about the Ethernet advanced physical layer (Ethernet-APL), or do you want to receive more information? We are happy to help! Simply fill out the contact form and send us a message.

More Information

More Information

+49 621 776-0

+49 621 776-0