Modernizing systems.

Saving costs.

Improving efficiency.

Remote I/O Gateway for Ethernet in Process Automation

Benefits

Ready for Big Data

Built-In Redundancy

Intuitive Usability

Ex-Protection 4.0—Integrated Communication in Process Plants

Field devices in process plants gather valuable additional data on their own condition and environment. Until now, this information could rarely be used due to a lack of continuous communication channels from the field to the control room.

But Industry 4.0 approaches like condition monitoring and predictive maintenance require this information. This is why we develop products like the new PROFINET gateway that are tailored to meet these demands. With its powerful processor and large memory, it builds a bridge between the field level and Ethernet-based network structures.

In addition to advanced product solutions, we also team up with various partners to maximize data availability—whether in the control room, cloud-based systems, or even on mobile devices. For us, this is Ex-Protection 4.0.

The Next Generation of Data Communication in Process Industries

The PROFINET gateway supports HART/HART IP to transmit process variables and additional status information from field devices. At the same time, HART IP can be used to effectively manage assets.

What’s more, with two Ethernet interfaces and integrated MRP (media redundancy protocol), the new PROFINET gateway is ideally suited for setting up high availability ring networks. When necessary, the redundancy manager initiates automatic network reconfiguration, ensuring the communication of segments that are unaffected by the failure.

The PROFINET gateway was developed in accordance with state-of-the-art security standards. Security features include a firewall and a read-only file system to prevent malware infections.

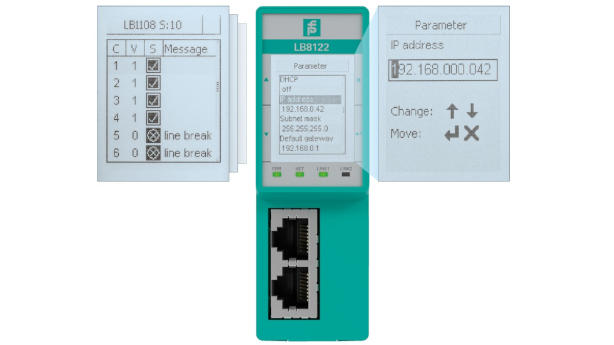

Large Touch Display for On-Site Diagnostics and Status Information

The PROFINET gateway features the largest touch display available on the market for this type of device. RGB LEDs and display symbols comply with the NAMUR 107 standard and indicate device and field unit status by displaying diagnostic and status information in a clear and standardized way.

Possible checks include status of communication with the master system, internal bus status, HART device recognition, and identification of faulty modules. This reduces downtime and costs. The gateway can be conveniently configured in the field via the touch display.

Opening the Door to Industry 4.0

The new, Zone 2, Class I/Div. 2 certified remote I/O PROFINET gateway from Pepperl+Fuchs opens the door for Industry 4.0 applications in process industries while simultaneously setting new standards in terms of handling, user friendliness, and security.

Different Information—One Connection

The PROFINET gateway supports HART/HART IP and enables the transmission of process variables and additional status information from field devices at high speed.

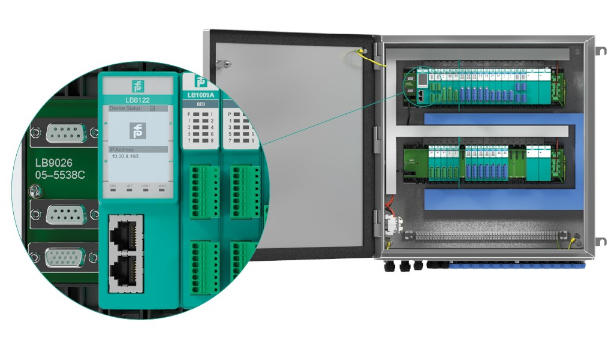

The PROFINET Gateway—Part of the Trusted LB Remote I/O System

Mounted on a standard DIN rail, the LB system is a real efficiency booster. The product range includes a variety of modules with different functions and channel numbers. You can assemble a remote IO solution to fit your application—while saving space.

In addition to remote I/O components, we can offer you a solution from one of our Solution Engineering Centers (SECs). Contact your local Pepperl+Fuchs representative, and our dedicated engineers will work with you to evaluate your requirements. The result is a fully certified, turnkey remote I/O field station.

Pepperl+Fuchs has pioneered electrical explosion protection since its early days. We know explosion protection standards all over the world and across all industries, and we channel this expertise into smart solutions like the LB system. Choose a trusted partner and benefit from the experience that comes with decades of engineering.

Learn More

Learn More Downloads

Downloads

+49 621 776-0

+49 621 776-0