Building on experience.

Driving technology.

Maximizing performance.

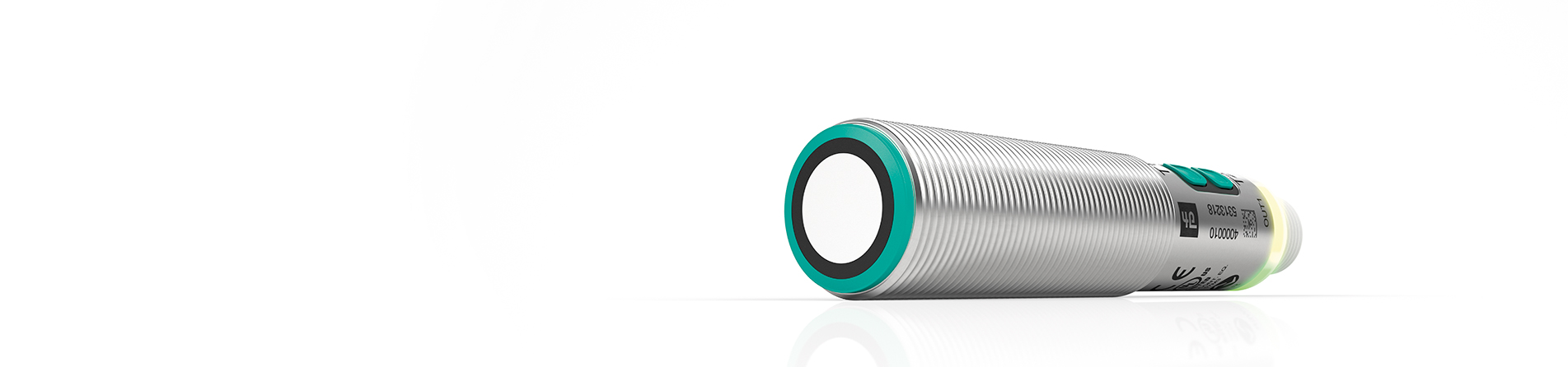

Ultrasonic Sensor

Series UC18GS with IO-Link

Benefits

Application-Specific Adaption

Easy Synchronization of Multiple Sensors

Extensive Programming Options

In More Detail …

360°

IO-Link: The Intelligent Communication Technology

An internationally standardized, cross-vendor open interface, IO-Link is an integral part of Pepperl+Fuchs’ Sensorik4.0® solutions. It is standardized according to IEC 61131-9 and is compatible with any fieldbus on the market.

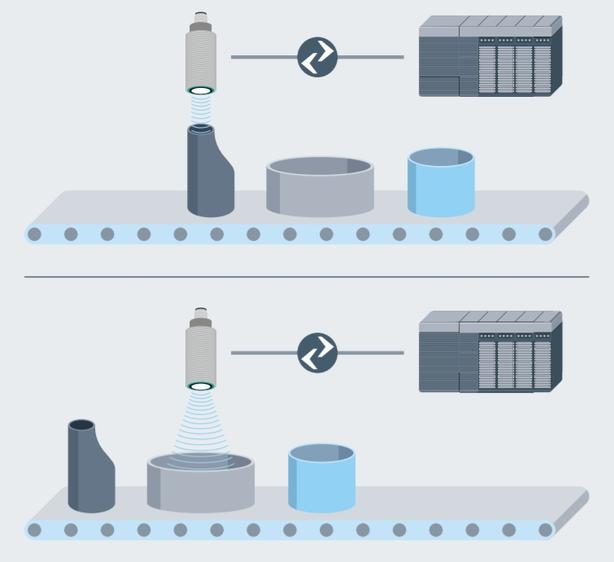

IO-Link sensors like the UC18GS can be configured via the control system. This simplifies commissioning and makes quick recipe changes possible without extended downtime. Even complete individualization—batch size 1 production—is possible. For example, the beam width on an UC18GS ultrasonic sensor can be adjusted to accommodate different container shapes in a level measurement application.

Trust the Ultrasonic Sensor Experts

In-House Quality That You Can Rely On

Ultrasonic sensors from Pepperl+Fuchs are built in our own technology center, where transducer development and manufacturing take place. For more than 30 years, our forward-thinking team of experts has been working continually to advance ultrasonic technology for the solutions of tomorrow. That means our customers always receive the highest performance products on the market.

This approach has led to the broadest portfolio in the industry— supported by numerous patents and innovations—for the highest level of flexibility in product selection and optimal application solutions. In addition to our standard portfolio, Pepperl+Fuchs has the knowledge and infrastructure to respond to customer requirements with speed and flexibility.

What's more, our extensive range of accessories offers you the right modules for customized integration, whether in tough installation conditions or for special applications, custom programming, and coordinated connection technology. They turn any sensor application into a high-performance, future-proof system solution.

Ultrasonic Technology Guides—Get Your Free Download Now!

In our downloadable documents, we share our expertise with you—sign-up for your free digital copies of our technology guides on ultrasonic sensors now! They will help you select the ideal sensor for your applications and get the most out of your device.

Downloads

Downloads More Information

More Information

+49 621 776-0

+49 621 776-0