PMI Inductive Analog Sensors for Metal Detection

Alternative application for inductive positioning systems

Production of printed circuit boards (PCBs) includes work processes in which stacks of PCBs are separated by suction grippers.

Generally a metal-free separation layer between 2 PCBs protects them from damage. If packaging is performed incorrectly, this order is not always maintained.

The gripper must therefore be able to detect whether it is dealing with the laminated PCB material or just with a separation layer.

In the past, this task was generally performed by expensive color sensors that had to be reprogrammed with a TEACH-IN procedure for each new color encountered.

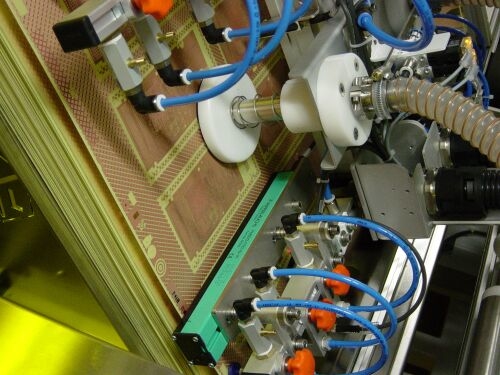

Fig. 1: PMI210-F110-IU-V1 detecting PCB

The inductive analog PMI sensor (see Fig. 1) offers a completely new way to perform this task.

The inductive sensor's wide measurement window allows it to detect a large amount of the PCB material. It even works for topologies with just a few tracks.

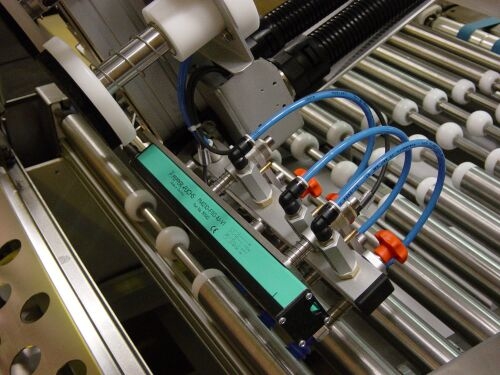

With spring suspension, it exerts gentle pressure against the PCBs and separation layers, evening out any small ripples in the plates (see Fig. 2).

Due to the analog output, precise control system measurement is possible.

The inductive sensor is sensitive enough to detect PCBs with just a few copper tracks, but insensitive enough not to detect through a separation layer, thereby detecting the next or previous PCB.

Because of this inductive procedure, there is no need for a new TEACH-IN process when the color of materials changes.

Fig. 2: PMI210-F110-IU-V1 with spring suspension for detecting PCBs

+49 621 776-0

+49 621 776-0