A Scanner for Any Situation - VB14N Barcode Scanners in Logistics Company Warehouses

Reliable solution for all reading applications

The VB14N barcode scanner is a reliable solution for all kinds of reading applications.

Modern material handling facilities often vary greatly in terms of building layout and design. Based on the structural features of each building, there are different distance and orientation mounting options for barcode scanners monitoring the flow of goods through the facility.

To ensure that transported material is reliably identified at exactly the right time, flexible scanner hardware is essential. With its extensive range of accessories, the VB14N barcode scanner is a reliable solution for all kinds of reading applications. It also reduces the number of scanner types required in the facility from at least three to just one.

Different requirements, one solution

In logistics company warehouses, the end-to-end flow of goods through the facility is coordinated using barcodes. In the incoming goods area, the barcodes on shipments from various suppliers are positioned at different heights. An oscillating mirror scanner is required to read barcodes on the side of packages. The OM-VB14N oscillating mirror attachment enables the VB14N barcode scanner to perform this task. The products are transported through the facility on trays. Usually, this means that the barcode must be read from the side. However, the space available for scanner mounting may be limited to just a few centimeters where conveyor belts are positioned in adjacent rows. A scanner with a side optical face is the solution, and the DM-VB14N deviation mirror allows the VB14N to complete this task with ease.

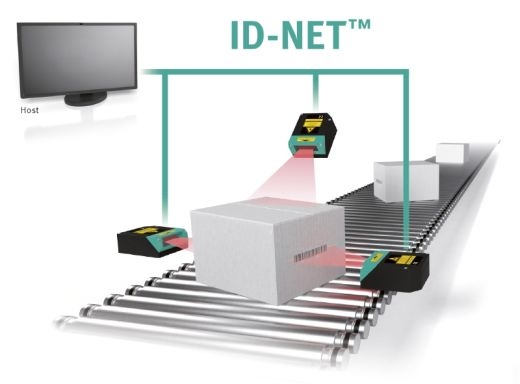

Multi-sided reading with the VB14N barcode scanner

At certain points during the process, the trays are turned and transported sideways. The barcode is then positioned in front of the package and is read from the top. In this scenario, the barcode needs to be read at an angle of up to 45 degrees, so the VB14N barcode scanner is used without a deviation mirror. In the outgoing goods area, the packages are positioned so that the barcode is always on one of two sides. Depending on the size of the package, it is mounted in ladder orientation and at different heights. In these situations, barcode scanners with large read field widths and networking capability must be present on both sides of the packages. Because up to 32 VB14N scanners can be networked together using ID-NET, these scanners are also suitable for use in this scenario.

Benefits of the VB14N barcode scanner

- Excellent read performance even with low barcode contrast

- Easy Teach-in of codes via mode button

- Up to 32 scanners can be connected to one another via ID-NET™

- Ideal for cold storage applications down to -35 °C

- Wide range of accessories for high flexibility

+49 621 776-0

+49 621 776-0