WirelessHART: Radio Technology in Process Engineering

A request becomes reality

Following the technological progress of field bus, the next development step in field communication is that of solutions involving radio technology. Although proprietary solutions have been available for a while, a wider application range is still waiting in the wings due to a lack of confidence in radio technology and the absence of integrated systems. Can radio technology be used on an 'across the board' basis, and if so, when?

It must first be established that in the transfer of measured values of safety-critical data and of data directly associated with process control, the cable represents the best available method for signal transfer. A cable-based solution should always be preferred to a radio technology solution for critical control applications. But if the plant construction is such that the remaining non-critical applications do not justify the installation of a cable, then radio technology has a role to play.

In which situations can the cable be eliminated?

Cable solutions are not necessary in smaller plants and in logistics operations where intermediate materials are stored, there may be no instrumentation and thus no feedback on storage levels. Cable solutions may also be discounted for economic reasons because there are obstacles between the control system and the plant itself. Level measurements, which are currently taken manually, can easily be replaced by a radio control method. Here there is no necessity for real-time transfer, and if a level value cannot be transmitted for a short period, it will not interfere with the operation of the plant.

There are also new possibilities in the sphere of environmental monitoring. One example is corrosion measurement using CorrTran® MV from Pepperl+Fuchs. Corrosion measurement is applied to critical areas of a vessel or pipeline. These positions are often extremely difficult to access or far away from the control system. A wireless CorrTran® MV can be optimally installed without an extensive wiring. Here, the security of the transmission is not a critical application, and since corrosion is an extremely slow process, it is not time-critical.

Another new possibility is the monitoring of operating elements that are actuated in the field, such as ball valves. Previously the status of such valves had been visually monitored by patrol checks carried out by employees. However, through wireless transmission of the ball valve position, its status is available at all times in the control room. Cyclic patrol checks and confirmation of the correct position of valves before plant start-up are no longer necessary. This not only saves a few Euros in labor costs, plant start-up is faster and production rates are higher. Of course the same applies to all the other manually checked status parameters, such as pressure and temperature.

Radio transmission can also be used for quality assurance and the optimization of important process parameters. These parameters, typically less critical to the process control, are often only temporarily monitored, in the event of the isolation of faults, for example, and in temporary plant installations with low volume requirements and frequent product changeovers.

In these applications, wireless technology improves the information on plant status, material flow and process sequence. It provides a basis for sequence and process optimization, asset management and decisions relating to preventive maintenance. Wireless technology improves the economy of process plants.

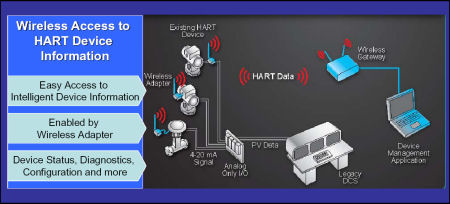

The existing infrastructure can be equipped with WirelessHART

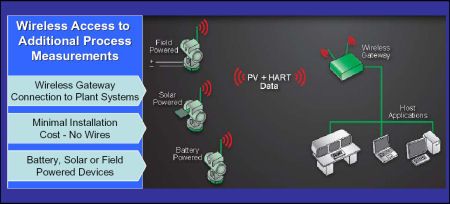

WirelessHART enables new applications to be better utilized

Wireless: It's already here

- Is convenient and simple to use

- Is available, as standard, from a number of manufacturers

- Satisfies the needs of process technology in terms of reliability of transmission and range

Such a system is now available from the HART Communication Foundation in the form of WirelessHART.

WirelessHART – now available

WirelessHART is built on the widely-used HART standard – as evidenced by 20 million HART compatible field devices. HART was originally conceived as an extension of the common 4 … 20 mA current loop, in order to provide field devices with greater functionality.

Now the next step in the evolution of HART has arrived. The WirelessHART Standard, released in September 2007, is based directly on the HART protocol, but is free of the physical transfer path. HART uses a 2.4 GHz band – license-free and used throughout the world – as a transfer medium for several radio technologies, including WLAN, Bluetooth, and ZigBee. In order to avoid collisions in the 2.4 GHz frequency band, WirelessHART carries out a special search for unused channels within this frequency band and keeps the mutual interference of radio technologies in check.

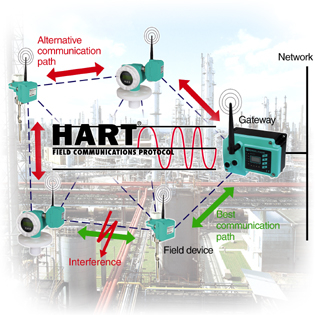

Evolution of a technology

WirelessHART uses a Flat Mesh Network where all radio stations form a network in which every participating station serves simultaneously as a signal source and a repeater. The original transmitter sends a message to its nearest neighbor, which passes this message on, until the message reaches the base station and the actual receiver. In this way the network covers a large area. In addition, alternative routes are set up in the initialization phase. In the event that the message cannot be transmitted on a particular path, for example due to an obstacle or a defective receiver, the message is automatically passed on to an alternative route. In addition to the coverage of larger areas, the reliability of transmission is increased.

The WirelessHART Network offers greater transmission security through alternative and redundant transmission paths

WirelessHART is the symbiosis between the much used and proven HART and the new radio technology – at least new to process technology. In addition to the well-known HART application for device parameterization, HART has already been widely used for:

- Monitoring of instrument and environmental values

- Asset management and optimization

- Preventive maintenance

- Performance monitoring

- Energy management

The requirements of these applications in terms of availability, transmission paths and speeds are well-matched by the performance capability achievable by radio technology. And the WirelessHART concept also offers a seamless integration in the existing infrastructure, with simultaneous openness with respect to new structures.

Mere theory, or achievable concepts?

At present Pepperl+Fuchs is developing the following devices:

A WirelessHART Gateway that manages the wireless network and connects it to a control or SCADA system via a field bus. The signals of the field devices are received and passed on via the appropriate bus protocol in the field bus.

A WirelessHART Adapter that forms the other end of the communication path. Existing field devices can be equipped with this adapter. Three different versions are planned:

- Loop-fed adapters are simply looped into an existing loop where they extract the energy for operation. The existing wiring is used for the conventional 4-20 mA signal transfer; HART is sent wireless via the adapter. Above all, this is an alternative, in order to render the HART capability in the field devices of the installed base usable with low risk.

- Battery-powered adapters supply the field device by means of a battery. At parameterizable intervals the field device is "awakened", the measured value is interrogated, and the field device switches off. Autonomous measuring stations are possible. Depending on the selected time intervals, a battery life of several years can be achieved.

- An externally powered version obtains the necessary energy for the field device and the adapter. In many cases an externally powered connection is available in the field, for example to supply pumps and valves. If no field device is connected, then this version can also serve as a router, in order to make the wireless network denser or to bridge a greater distance.

Summary

Radio technology enables better utilization of existing applications and the achievement of new, cost-effective applications that were not previously possible. WirelessHART provides the necessary step from proprietary solutions to an overall standard in process technology, which enables the use of radio technology without system breakdown. WirelessHART will open up new possibilities to improve quality and plant monitoring, and optimize plants and processes. It is a worthwhile contribution to the economic operation of process plants.

+49 621 776-0

+49 621 776-0