Safe Positioning Using the PMI360D

Inductive analog measurement system

A set-down packer places beer crates from conveyor belt A onto conveyor belt B. The transfer of the crates requires a position detection from 0° to 360°, with conveyor belt A representing the 0° position (4 mA) and conveyor belt B the 360° target position

In this case an analog output is required. Rotary encoders proved to be an ineffective solution.

Task

Previously, an analog sensor was used for this application, which was attenuated by an inclined target.

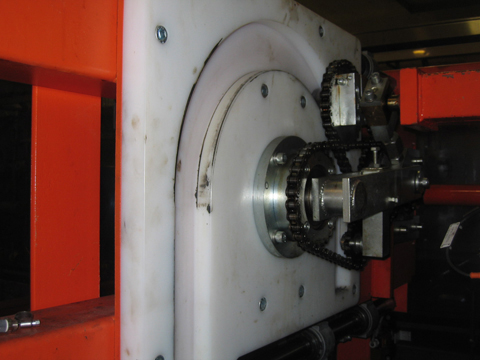

Fig. 1: chain drive graph

Although it was possible to establish the initial position, slight inaccuracies in the chain drive sometimes caused the target to move outside the sensor’s detection range; incorrect readings were inevitable.

Implementation

The PMI360D-F130-IE8-V15 analog meaurement system from Pepperl+Fuchs is mounted directly onto the shaft of the chain drive. The required distance 4 mA … 20 mA positions from 0° … 360° are detected with absolutely no errors.

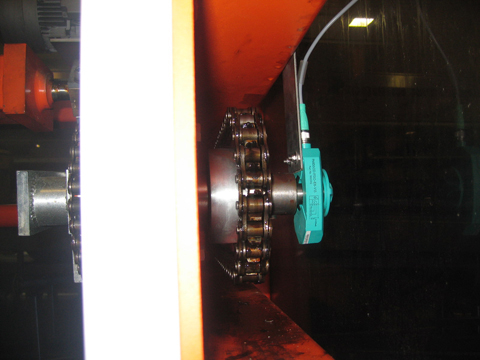

Fig. 2: shaft with analog measuring system PMI360D

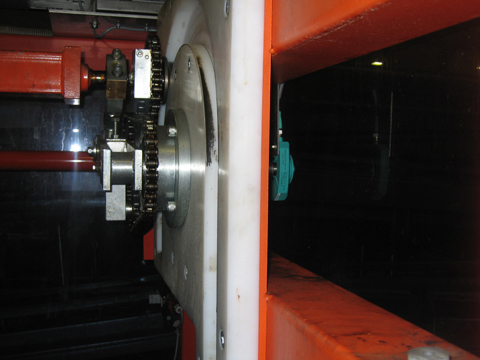

Fig. 3: drive with analog measuring system PMI360D

Customer Benefits

The PMI360D-F130-IE8-V15 analog measurement system from Pepperl+Fuchs is reliable and guarantees an error-free production process.

+49 621 776-0

+49 621 776-0